Common Fabric Defects in Garment Manufacturing and How to Identify Them During Inspection

In the world of garment manufacturing, fabric is the foundation of quality. Even the most skilled tailoring and advanced machinery cannot compensate for defective fabric. Whether it's subtle color shading or major weaving flaws, fabric defects can compromise a brand’s reputation and lead to costly returns, rework or product recalls. This makes identifying and addressing fabric defects during inspection a critical step in the quality control process.

This blog explores the most common fabric defects found in garment manufacturing and how professional inspections help detect these issues early in the supply chain. Whether you're a buyer, supplier or manufacturer, understanding fabric defects is key to ensuring consistent product quality and customer satisfaction.

Why Fabric Quality Matters in Garment Manufacturing

Fabric accounts for nearly 60-70% of the cost of a garment. Therefore, any compromise in fabric quality directly impacts the product’s overall value. Defects in fabric not only lead to aesthetic or structural problems but can also cause manufacturing delays, wastage and compliance issues.

Moreover, defective garments can erode brand trust. Consumers expect durable, well-finished clothing free from visible or functional flaws. When these expectations are not met, returns spike and customer loyalty suffers. A robust fabric inspection process—especially one conducted by an experienced third-party inspection company—plays a vital role in mitigating these risks.

Explore Testcoo's Ultimate Guide to Garment and Apparel Inspection

What Are Fabric Defects?

Fabric defects are flaws or irregularities that occur during the textile production process. These can be due to various reasons such as machine malfunctions, poor raw materials, human error or environmental factors. Defects may appear during:

- Weaving or knitting

- Dyeing and printing

- Finishing and coating

Fabric defects can be categorized as either major or minor, depending on their severity and visibility in the finished garment. While some are purely cosmetic, others can significantly affect the usability or longevity of the product.

10 Common Fabric Defects and Their Causes

Let’s dive into the most frequently observed fabric defects in the garment industry and how to identify them during inspection.

1. Color Shading

Description: Noticeable differences in color shades between different parts of the same fabric roll or between different rolls.

Cause: Variations in dyeing batches, inconsistent fabric absorption or machine inconsistencies.

Inspection Tip: Compare rolls side by side under consistent lighting conditions. Use a grey scale for color assessment.

2. Dye Streaks or Dye Marks

Description: Unwanted streaks, lines or blotches caused by uneven dye penetration.

Cause: Dyeing machine malfunction, uneven fabric tension or poor dye mixing.

Inspection Tip: Examine fabric rolls under both natural and artificial light to spot inconsistent coloration or streaks.

3. Holes or Slubs

Description: Small holes, tears or thick uneven yarns (slubs) that distort fabric uniformity.

Cause: Yarn breakage, poor spinning, insect damage or mechanical abrasion during production.

Inspection Tip: Use a lightbox or backlighting during inspection to detect small holes or thin areas in the fabric.

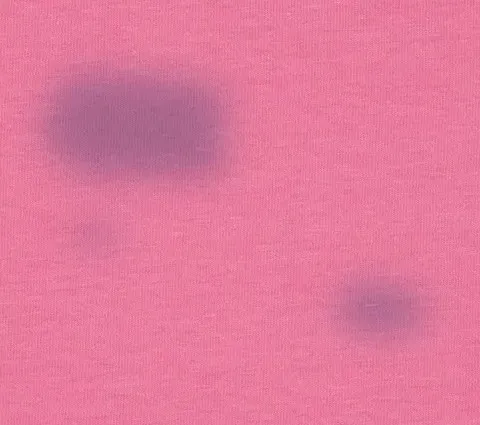

4. Weft or Warp Bar

Description: Visible horizontal or vertical lines that differ slightly in texture or color from the surrounding fabric.

Cause: Variations in yarn tension, mechanical faults or inconsistent dyeing.

Inspection Tip: Run your hand over the fabric to detect texture inconsistencies and view the fabric at different angles.

5. Misprints or Off-Register Prints

Description: In printed fabrics, designs may be misaligned, blurred or duplicated.

Cause: Printing plate misalignment or slippage during the printing process.

Inspection Tip: Inspect printed fabric for pattern consistency and alignment with design specifications.

6. Crease Marks or Pressure Marks

Description: Permanent creases or shiny lines on the fabric surface.

Cause: Excessive pressure during rolling, folding or storing of the fabric.

Inspection Tip: Observe the fabric in flat, open condition and look for reflective patches or unwanted lines.

7. Yarn Contamination

Description: Foreign fibers or colored threads embedded in the fabric.

Cause: Contamination during spinning, weaving or finishing stages.

Inspection Tip: Closely inspect light-colored fabrics for dark or colored threads using a magnifier if needed.

8. Uneven Texture or Thickness

Description: Areas that are thicker, thinner or rougher than the rest of the fabric.

Cause: Inconsistent yarn quality or knitting/weaving irregularities.

Inspection Tip: Check fabric hand-feel and thickness across multiple sections of the roll.

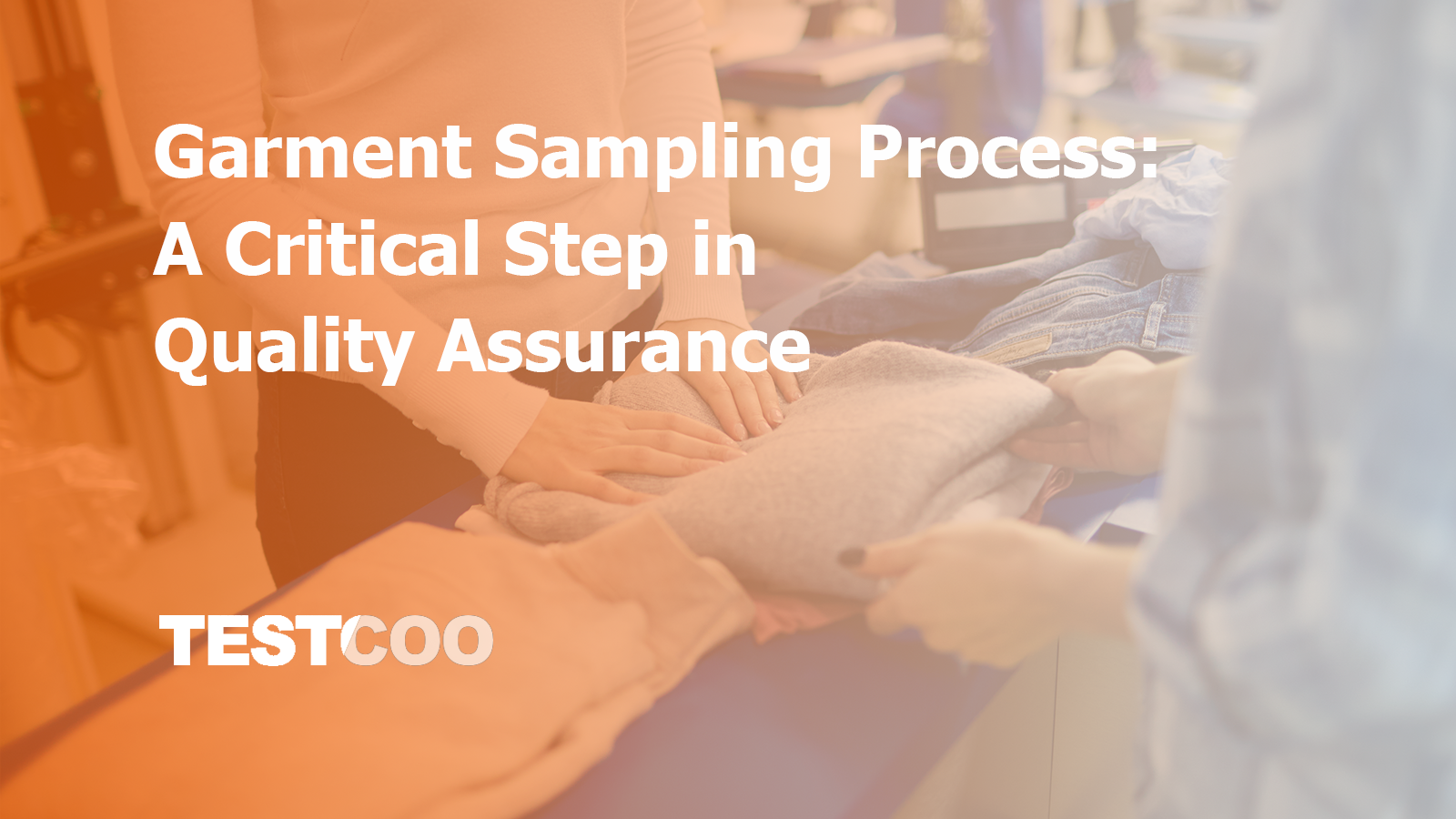

9. Chemical Stains or Oil Spots

Description: Discolored patches caused by chemicals or lubricants.

Cause: Machine oil drips, finishing chemicals or contaminated storage conditions.

Inspection Tip: Use visual inspection and smell to detect chemical presence and assess discoloration.

10. Skewing or Bowing

Description: Wavy or diagonal distortions in the fabric grain.

Cause: Improper tension settings during weaving or finishing.

Inspection Tip: Check straightness of the warp and weft lines using measurement guides or fabric inspection tables.

Read about TOP 10 Common Defects in Garments Quality Inspection

The Role of Fabric Inspection in Quality Control

Fabric inspection is the process of systematically checking fabric for defects before it is cut and sewn into garments. This typically happens either at the mill (mill inspection), during in-house quality control or via third-party inspection services.

Objectives of Fabric Inspection:

- Detect and classify visible and invisible defects

- Ensure fabric conforms to buyer specifications

- Determine defect levels based on AQL (Acceptable Quality Limit) standards

- Identify root causes and communicate feedback to suppliers

Fabric Inspection Methods Used by Professionals

Several methods are commonly used to inspect fabrics effectively:

1. 4-Point System

4-Point System is the most widely adopted grading method. Points are assigned based on the severity and size of each defect:

- 1 point: defect up to 3 inches

- 2 points: defect 3–6 inches

- 3 points: defect 6–9 inches

- 4 points: defect >9 inches or holes

A roll is accepted if the total points per 100 square yards are below the buyer's tolerance level.

2. 10-Point System

Each defect is assigned 1 to 10 points depending on type and severity. A lower score indicates higher quality.

3. Graniteville “78” System

Mainly used in the U.S., this assigns demerit scores and classifies fabrics into First or Second quality.

4. Fabric Inspection Machines

Specialized machines with backlights and defect marking tools help inspectors identify flaws accurately and efficiently.

Best Practices for Conducting Fabric Inspections

To ensure that no defect goes unnoticed, third-party inspection teams follow a structured inspection protocol:

- Inspect at least 10% of rolls or as per sampling plan (e.g., AQL 2.5)

- Unroll fabric at a speed slow enough to detect issues (~15 yards per minute)

- Use proper lighting and viewing angles

- Document all findings with photos and defect maps

- Classify defects as major/minor/critical

- Communicate detailed reports to both buyer and supplier

How Buyers Can Minimize Fabric Defects

While inspection helps identify defects, prevention is even better. Here’s how buyers and brands can reduce fabric-related issues:

- Work with certified mills that follow strict quality controls

- Define clear fabric specifications in purchase orders

- Request fabric swatch approval before bulk production

- Conduct fabric testing (e.g., GSM, colorfastness, shrinkage) in addition to visual inspection

- Use third-party inspection services for unbiased assessments

Benefits of Third-Party Fabric Inspections

Hiring a professional third-party inspection company like Testcoo offers multiple advantages:

- Unbiased assessment: Neutral inspectors evaluate fabric quality without internal influence.

- Global presence: Inspectors available at mills across manufacturing hubs.

- Standardized checklists: Product inspection checklist aligned with buyer expectations and industry best practices.

- Real-time reporting: Digital tools and dashboards for instant access to inspection data.

- Reduced risk: Early detection avoids further processing costs or shipment delays.

Minimize Fabric Defects with Testcoo’s Expert Inspection Services

Fabric defects are an unavoidable reality in the garment manufacturing process, but their impact can be minimized with timely and professional inspection. From dye marks and slubs to misprints and contamination, every issue has a potential solution—starting with awareness and prevention.

By partnering with experienced third-party inspection firm like Testcoo, brands and manufacturers can ensure that only high-quality fabric makes its way into production. This not only safeguards your product integrity but also enhances customer satisfaction and brand loyalty in a competitive apparel market.

Testcoo’s experienced inspectors and standardized processes ensure every roll meets your specifications before production begins. Contact us today to learn more about our fabric inspection services.

inspection report

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index