TOP 10 Common Defects in Garments Quality Inspection

The?revenue of the global apparel market?was calculated to amount to some 1.5 trillion U.S. dollars in 2021 and was predicted to increase to approximately 2 trillion dollars by 2026.?Besides China, some new sourcing destinations such as Vietnam, Thailand, Peru and Mexico, have developed their garment & textile industry?dramatically and the demand of?inspections in these countries?has increased.

Based on the quality control inspection statistics?from the most common garment?defects that have been found during?inspecting at garments’ suppliers in these countries, our inspectors have summarized the top 10 common defects in garments inspection checklist that buyers should know.

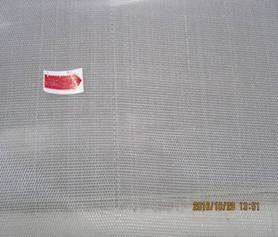

10. Broken pick

Cause:

?? A result of breaking or cutting the filling yarn, which leads to the insertion of a partial separation into the fabric.

?? May occur after a weft rupture, weft exhaustion, or a faulty weft fork mechanism.

Solution:

1) Correct weft stop motion.

2) Training?the weaving personnel in identifying and replacing?a broken piece during production can help prevent this defect from appearing in the finished product.

9. Needle lines

Cause:

? Unskilled workers.

Solution:

1) If the needle lines are found, it is recommended to only trace the needle line to the corresponding defective needle and replace it to prevent further needle lines. If needle lines appear in the strip it is recommended to replace several broken needles.

2) Check if your supplier has developed and maintains proper maintenance and cleaning procedures to prevent problems with needles and equipment.

8. Hole

Cause:

? Caused by an accidental cut or tear.

? Broken needles or coarse mechanical parts.

Solution:

1) Ensure?that the supplier has procedures for regularly checking needles and ensure scissors are not abused.

7. Neps/ knots

Cause:

? Fly fiber falls on the yarn when spinning or untrimmed coarse yarn appears when weaving.

Solution:

1) Ensure proper maintenance?and cleanness?of machine and production environment.

2) Remove the neps before processing.

6. Open seam

Cause:

??Caused by an accidental?pulling.

? Poor quality thread and poor working machine.

Solution:

1) Take care of the garment when packaging.

2) The manufacture should produce the garment with better sourcing material.

3) Ensure proper maintenance?of working machine.

5. Misprinting, off printing or absence of printing

Cause:

? Printing plate is dislocation or fabric isn’t fixed when printing.

Solution:

1) The printing plate and fabric must fix when printing.

4. Drop stitches

Cause:

? A?broken?needle is used?when knitting.

Solution:

1) Use high-quality needles on the knitting machine.

2) Check the yarn holder and any other machine for proper tension during production to?prevent stitches from falling.

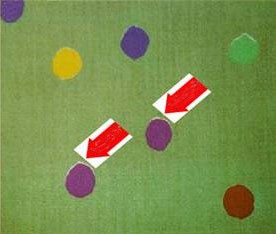

3. Uneven dyeing/ printing/ dye marks

Cause:

? Poor quality base fabric (dirty or fly yarn on the fabric surface before dyeing).

? Dyeing machine entanglement (dirty falls?on the fabric when printing).

Solution:

1) Ensure the cleanness of fabric before dyeing or printing.

2. Dirt/ stains

Cause:

? garment is not stored in an area with adequate protection after production.

? Fabrics easily get stains from any source: dirt from the plant, oil from sewing machine and dyes.

? Poor?quality of fabric.

Solution:

1) A manufacturer can prevent stains during production by regularly cleaning production machines and equipment to ensure no random oils, grease or dyes make their way onto the textile.

2) Wrapping the finished rolls of fabric in plastic and storing them in a separate area away from the dying area can ensure avoiding post-production stains.

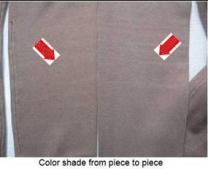

1. Shade variation

Cause:

? Variations in the production process in terms of time and speed (such as dye process)

? Wrong pile direction (for corduroy, velvet and polar fleece)

? Mixing fabrics used in manufacturing

? Incorrect trimming, bundling and / or numbering

Solution:

1) Using the same base material and parameter set for each production batch can effectively prevent a change in shade.

2) When visiting a factory that produces raw fabrics, make sure that workers combine clothes of the same color. Proper numbering of textile types prevents the erroneous combination of cuts that differ in shade.

A?clear understanding of the different types of fabric defects?in quality control inspection?will help buyers?to ensure the quality of the fabric that meets their standards.

As oversea buyers, if you want to avoid quality complaints and product returns, along with studying the quality system and potential defects, it is also an option to turn to a third-party inspection company.?TESTCOO?conducts plenty of inspections for textiles and fabrics, as well as for finished clothes, in China, India, Vietnam, Peru, Mexico etc. Full-time trained inspectors guarantee reliable professional inspection for your products while conducting specific on-site?tests to ensure the long-term quality of the goods and ultimately your reputation.

Free Sample Report Performance Quality Control

Download a sample report to keep control of your supply chain!

Featured Articles

AQL Table | How to Read It

AQL Table | How to Read It TOP 10 Common Defects in Garments Quality Inspection

TOP 10 Common Defects in Garments Quality Inspection Product Packaging and Shipment Label requirements for Amazon FBA

Product Packaging and Shipment Label requirements for Amazon FBA What Is ASTM-F2413-18? Protective Footwear Standard

What Is ASTM-F2413-18? Protective Footwear Standard How to Conduct Third-Party Quality Control Inspections for Electric Scooters

How to Conduct Third-Party Quality Control Inspections for Electric Scooters SMETA Audit-What is SMETA Audit?

SMETA Audit-What is SMETA Audit? TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS

TESTCOO Supplier Verification/Certification Service SLCP, Higg FEM, GRS, GOTS Quality Control Inspection Company in China

Quality Control Inspection Company in China What is Quality Inspection? A Complete Guide

What is Quality Inspection? A Complete Guide Guidelines for Product Inspection in India

Guidelines for Product Inspection in India

Category

- Production Inspection Service

- Factory Audit

- Softline Inspection

- Hardline Inspection

- Electrics Inspection

- Certification

- Checklist

- Manufacturers

- Quality Assurance Basics

- Products Recall

- AQL

- Guidence and Standard

- News

- Supplier Management

- Amazon

- Protective Equipment

- e-commerce quality control

- Indian Manufacturing

- Soft Goods Quality Control

- Supply Chain Management

- Supply Chain Resilience

- E-Commerce Quality Control

- ISO 2859

- Supply Chain Optimization

- Garment Industry

- Higg Index